Harmonizing heaven, earth, and humanity,

igniting the goodness and potential within individuals.Here, you will gain a comprehensive understanding of us. Welcome to establish further connections with us

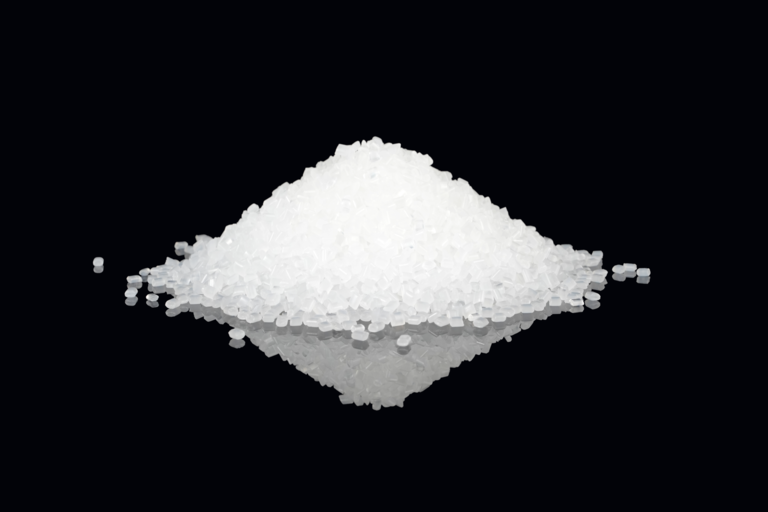

PP Coupling Agent

| Grades | Base Resin |

MFI(g/10min) [1]190℃,2.16kg [2]160℃,0.325kg |

Grafting Level (MAH wt%) |

Applications | ||

| GPM200A | PP-H | 70-100[1] | 0.5-1.0 |

Primarily used in glass fiber reinforced PP, inorganic powder reinforced PP, etc., with high fluidity and excellent processing performance. It is typically applied in PP/GF composite materials to aid the dispersion of glass fiber and prevent glass fiber from migrating/floating to the surface. Loading dosage 1.5-5%. |

||

| GPM200AL | PP-H | 30-50[2] | 0.2-0.5 |

Used for cast film, fiber and powder enhancement in PP. The fluidity is moderate, meeting the diverse needs of different customers. Loading dosage 1.5-5%. |

||

| GPM200B | PP-B | 30-50[2] | 0.2-0.6 |

Primarily utilized in fiber and inorganic powder filled PP, as well as serving as a compatibilizer for PP/polar resin alloys. Providing improved tensile and impact strength. Applications are PP/PA alloy and PP car bumpers. Loading dosage 2-5%. |

||